New multi-frequency + multi-channel heat treatment hardness material sorting technology

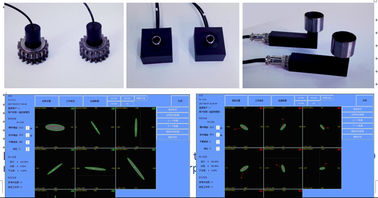

◆ HEF-6000S series intelligent digital vortex sorting instrument is especially suitable for heat treatment hardness sorting detection of automotive/aviation parts.

◆ The new software algorithm, better detection performance and higher noise-to-noise ratio than the peers, continuous software development, providing software free lifetime upgrades.

◆ With a single channel 8 frequency sorting function, it is also possible to work simultaneously on 8 channels of multiple channels.

◆ Material hardness, heat treatment, tensile strength, microstructure, mixing density of the mixture, etc., rapid sorting, non-destructive testing, no damage to parts and materials. Really achieve 8 frequencies simultaneous detection, higher detection accuracy, stability and reliability than single frequency detection. Eliminate all the differences may be missed.

◆ Customized probes are available to meet customer inspection needs. It can be manually tested in the laboratory, or it can integrate automated large-scale rapid detection and various I/O data interfaces, which can realize functions such as rapid automatic detection, automatic sorting, automatic alarm and automatic statistics.

◆ Powerful software features such as parameter storage, data storage, report analysis, and statistics.

◆ The instrument is simple, reasonable and intuitive to operate.

◆ Quickly switch between Chinese and English with one button, and quickly customize multi-language packs.

The advantages of multi-frequency sorting - more reliable sorting technology

For sorting with only two configurations, one detection frequency is sufficient. However, in the 100% online rapid inspection process, multi-frequency detection is one and only solution to prevent any wrong structure of the workpiece being inspected. Only qualified parts are used for calibration, no need to find the best sorting frequency, and the reliability is very high.

Eight frequency hardness / material / heat treatment / shape difference, etc.

- HEF-6000SF series of intelligent digital eddy current detectors have a single channel 8 frequency sorting function, and can also work simultaneously on 8 channels of multiple channels.

- Rapid sorting of material hardness, heat treatment, tensile strength, microstructure, and sintering density of the mixture. Really achieve 8 frequencies simultaneous detection, higher detection accuracy, stability and reliability than single frequency detection. Eliminate all the differences may be missed.

Customized probes are available to meet customer inspection needs. It can be manually tested in the laboratory, or it can integrate automated large-scale rapid detection and various I/O data interfaces, which can realize functions such as rapid automatic detection, automatic sorting, automatic alarm and automatic statistics.

For sorting with only two configurations, one detection frequency is sufficient. However, in the 100% online rapid inspection process, multi-frequency detection is one and only solution to prevent any wrong structure of the workpiece being inspected. Only qualified parts are used for calibration, no need to find the best sorting frequency, and the reliability is very high.

| Detection method |

Detection quantity |

Known OK |

NG |

NG pieces(not be detected) |

| Metallographic analysis |

2000 |

1884 |

116 |

0 |

| Normal single frequency detection |

2000 |

1884 |

81 |

35 |

|

HUATEC

multi-frequency detection

|

2000 |

1884 |

116 |

0 |

The HUATEC R&D team is one of the earliest R&D teams in China to contact the fully automated eddy current testing of auto parts. It is also the leader of the domestic high-end eddy current automation system, with multi-frequency multiple physical channels and various types of rotary scanning detection methods. At present, the detection of engine block detection, piston rod longitudinal crack detection, brake disc omni directional inspection, hub bearing unit, and various types of rotating body non-standard parts are in the leading position in China. The system combines the most advanced eddy current technology, photoelectric technology, and fully automatic detection mechanism controlled by microcomputer. It is easier and smarter to use. The instrument performance is stable and reliable, with high automation and fast detection speed. Flexible software package, such as flaw detection, octave hardness, material, heat treatment sorting, etc., and customizing various parts visual inspection package. Make the inspection process intuitive and convenient, and lead in the domestic industry.

◆ HUATEC is a leading provider of automated assembly lines and online testing equipment for auto parts. More than 40 automation companies and various parts manufacturers at home and abroad are equipped with high-performance testing instruments. Detection hardware, software, and probes can be configured according to different inspection workpieces and different detection requirements.

We will consider the inspection requirements for the extension of the parts processing technology.

◆The research and development team's research on the details is the ultimate, and it is more understanding of the field conditions and needs.

◆Control workpiece runout, durability, processing straightness, roughness, materials, heat treatment and other details.

◆In the process of customer use: the requirements for personnel are reduced as much as possible, mainly reflected in the fooling and visual design of the software.

◆We considered the cost of staffing for our customers and we considered ergonomics.

◆We considered a modular design that made the equipment durable and low cost after the sale, and we considered saving on site costs. ◆

◆We will even consider the customer input-output ratio to tailor the detection method, the degree of automation and other factors.

Quickly customize a variety of high performance and cost effective probes

◆It can flexibly and quickly customize all kinds of high-performance, cost-effective detection probes (point type, plane, inner wear, outer wear, sorting and other high-performance detection probes such as probes and rotary sweepers).

| Technical specification |

|

◆ Detection channel: 1-16 (continuous expansion of 256 channels as needed)

◆ Frequency range: 10 Hz~12MHz, continuously adjustable; multiple independent frequencies, single frequency, 8 frequency options (up to 16 software frequencies per channel);

◆ The system is based on WINDOWS development, and the system is permanently upgraded for free;

◆ Gain range: 0.0dB~99.0dB continuously adjustable, stepping: 0.1dB; fine-tuning, fast increase/decrease;

◆ Gain ratio: (X/Y) 0.1~10.0; continuously adjustable, fine-tuning, fast increase/decrease;

◆ Signal to noise ratio ≥10dB (up to 30db);

◆ Phase rotation: 0~360° continuously adjustable, stepping: 1;

◆ Adjustable probe drive (excitation) level: 1 to 16 ;

◆ Filter coefficient:0-30000;

◆ Adjustable detection range, ie maximum measurement value: 10~10000, step 1;

◆ Hardware amplification factor: 1dB ~ 32dB continuously adjustable, step: 1dB;

◆ Multiple excitation modes: DP/DI; can be configured with differential, absolute and various custom probes.

◆ Probe abnormal alarm function (viewing model)

◆ Fast digital balance;

◆ The solid line and blanking display modes are flexible and optional;

◆ Blanking display coefficient: 1 ~ 400;

◆ Digital filtering: low-pass (0Hz ~ 2000Hz) high-pass (0Hz ~ 2000Hz); using a unique "digital filtering" to effectively suppress the on-site interference signal, to ensure the accuracy and stability of the detection;

◆ Stability: 16 hours ≦ 2dB;

◆ The utility model has the function of cutting off the end and end tail signals, and effectively controlling the end dead zone of the end;

◆ The alarm duration can be adjusted: 10ms~60000ms, stepping 1ms;

◆ Missing rate: ≤ 0%, false positive rate (falsely judged as a non-conforming product by mistake) ≤ 1%;

◆ Flexible internal and external clock selection

◆ Real-time software/hardware output alarm, multiple alarm window modes (circular, square, fan-shaped, custom type), with alarm, pre-alarm function, and can output signals separately;

◆ Non-equal amplitude, asymmetric phase alarm zone setting;

◆ Multiple display modes: impedance, time base, AB sweep, 8 frequency sorting, analog 3D display (depending on model selection);

◆ With a unique time base alarm reference line, more intuitive detection data display.

◆ The eddy current signal playback extension function can measure the amplitude, phase and digital value of the defect;

◆ Cartesian coordinate system and polar coordinate system background selection;

◆ Automatically form test reports (including the number of tests, test personnel, test parameters, number of pass and number of non-conformities, etc.) that require peripheral support;

◆ One-click switching between Chinese and English operating languages, no need to install an operating system or online help;

◆ Working environment: Power supply: AC 220V/110V;

◆ Working temperature: 0 ° C ~ +45 ° C, storage temperature: -20 ° C ~ +50 ° C, relative humidity: ≤ 85%;

◆ The cross-sectional view of the in-service pipeline, the rank of the pipe to be inspected, and the eddy current detection signal (optional) can be displayed on the same screen;

◆ The plane for installation of each flaw detector is: 550 × 1000mm2, and the signal line can be either side wall or bottom.

◆ Appearance size and weight:500*500*260mm (L*W*H),Weight:5kg.(without display)

◆ Optional small industrial control type, horizontal industrial control type, 5U industrial control type (with display)

|

| Application Area |

| ◆ Automobile, aviation parts testing, automated testing line matching, laboratory research, etc. |

| Configuration instructions |

|

◆ Host: HEF-6000S Multi-function intelligent digital eddy current detector (detection + sorting)

◆ Probes and accessories: can be customized according to user's materials, specifications and shapes (standard probes are configured by channel number)

◆ Standard test block: (optional or customized)

◆ Instruction manual: one

◆ Warranty card: one

◆ Product list: one

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!