Product Description:

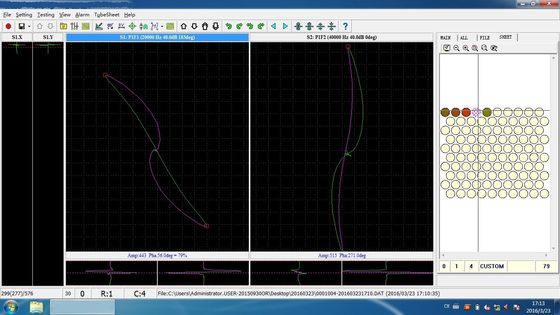

Eddy Current Testing Equipment is a state-of-the-art flaw detector system used to detect flaws in various materials. It utilizes eddy current technology to detect any kind of discontinuity or small defects in metallic and non-metallic materials. The eddy current testing equipment can detect defects that are not visible to the naked eye. It offers a wide range of advanced features such as background coordinate, impedance display mode, mixing unit to suppress noise signal at a constant frequency, probe type, and automatic generation of report in different formats.

The background coordinate of the eddy current testing equipment comes in both rectangular and polar coordinate. It also has an impedance display mode with point, line, and auto options. Its mixing unit helps to suppress noise signal at a constant frequency. In terms of probe type, the eddy current testing equipment offers differential, absolute, DP, encircling coil, pencil, flat, sector, array, etc. It also has the capability of automatically generating reports in different formats.

The eddy current testing equipment is an essential tool for any industries that require flaw detection. It is capable of detecting defects that are not visible to the naked eye, offering a wide range of options and features. The eddy current flaw detector, eddy current testing machine, and eddy current equipment are all excellent tools for accurate and reliable flaw detection.

Features:

- Product Name: Eddy Current Testing Equipment

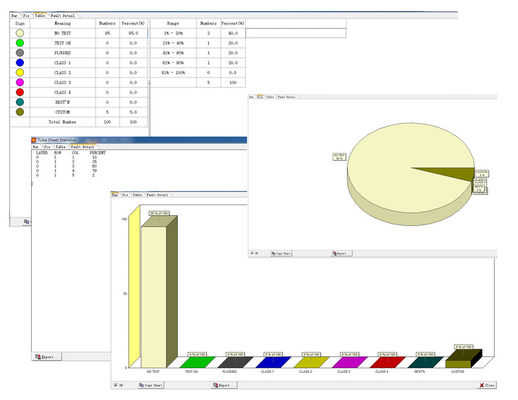

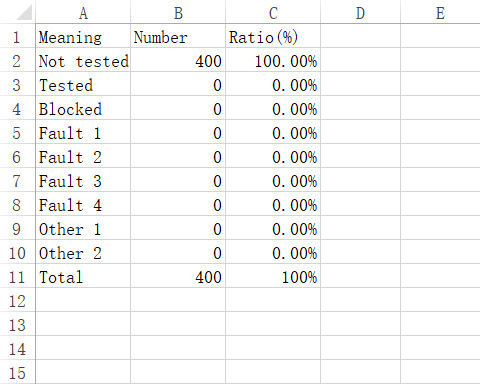

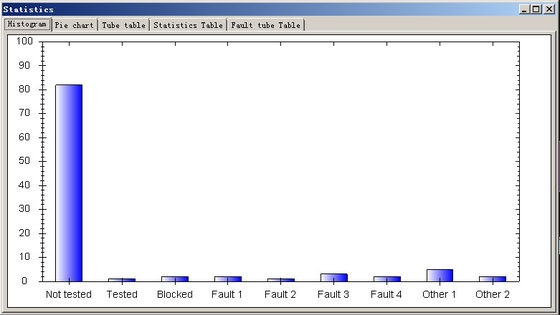

- Report: Automatic Generation Of Report In Different Format

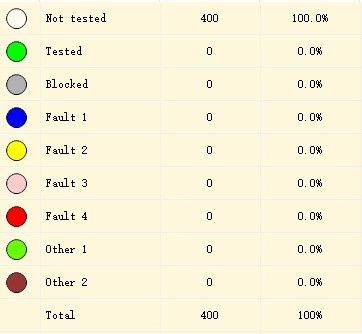

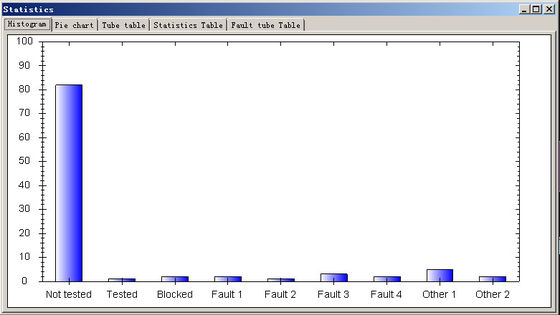

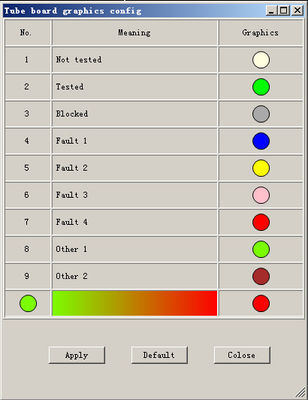

- Tube Sheet Mapping: Tube Sheet Mapping Draws According To Real Tube Layout,and Testing Result Is Marked In Different Colors

- Power supply: 100-240V 50/60Hz

- Gain Ratio (Y/: 0.1-10

- Channel: 2 Channels

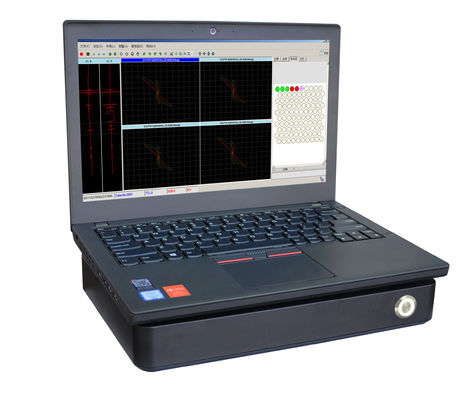

- Eddy current flaw detector: Portable eddy current flaw detector

- Eddy current equipment: High precision eddy current equipment

Technical Parameters:

| Parameter |

Value |

| Gain Ratio (Y/: |

0.1-10 |

| Screen Display |

Real-time Strip Chart, Impedance Plane, Tube Sheet Display |

| Report |

Automatic Generation Of Report In Different Format |

| Product Name |

Eddy Current Testing Equipment |

| Frequency |

2 Frequencies Per Channel With 64Hz-5MHz For ECT, 5Hz-5KHz For RFT |

| Power supply |

100-240V 50/60Hz |

| Machine size |

290mm X 210mm X 42.5mm |

| Phase |

0-359 In 0.1steps |

| Alarm Output |

One Hardware Alarm Output With Triode OC Gate |

| Balance |

Fast Digital/analog Electronic Balance |

Applications:

HUATEC HEF-C35RFT eddy current testing equipment is an ideal choice for non-destructive testing of metals and alloys. The equipment is designed with 2 frequencies per channel, ranging from 64Hz-5MHz for eddy current testing and 5Hz-5KHz for rft, which greatly improves the accuracy and efficiency of testing. It has a real-time strip chart, impedance plane, and tube sheet display, which enable users to easily view the testing result. The gain ratio (Y/X) is adjustable from 0.1-10, and the tube sheet mapping draws according to real tube layout, with the testing result marked in different colors. The calibration can be done on known flaws and also generates the calibration curve automatically. All of the calibration data can be saved and called up when needed. The product has CE certification, with a minimum order quantity of 1pc and a supply ability of 100pcs per month. It is packaged in a standard carton and requires a 5-day delivery time. Payment terms include T/T or L/C.

Customization:

Eddy Current Testing Equipment - HUATEC HEF-C35RFT

Brand Name: HUATEC

Model Number: HEF-C35RFT

Place of Origin: China

Certification: CE

Minimum Order Quantity: 1pc

Packaging Details: Standard carton

Delivery Time: 5 days

Payment Terms: T/T L/C

Supply Ability: 100pcs per month

Impedance Display Mode: Point, Line, Auto

Tube Sheet Mapping: Tube Sheet Mapping Draws According To Real Tube Layout,and Testing Result Is Marked In Different Colors

Background Coordinate: Rectangular Coordinate, Polar Coordinate

Machine weight: 2.0kg

Mixing Unit: Mixing Unit To Suppress Noise Signal At A Constant Frequency

HUATEC HEF-C35RFT is a portable eddy current flaw detector, a type of eddy current testing machine. It is designed to meet the needs of the most demanding applications. This machine provides high accuracy and outstanding performance in all types of field testing. The machine is lightweight, compact and highly portable. It also has a wide range of features and functions to ensure the testing results are accurate and reliable.

Support and Services:

Technical Support and Service for Eddy Current Testing Equipment:

- Provide technical advice and operational assistance for Eddy Current Testing Equipment

- Provide technical training for Eddy Current Testing Equipment

- Provide remote technical support and software update services

- Provide repair and maintenance services for Eddy Current Testing Equipment

- Provide spare parts and accessories for Eddy Current Testing Equipment

- Provide warranty service for Eddy Current Testing Equipment

Packing and Shipping:

The Eddy Current Testing Equipment will be packaged in a secure and durable box, with additional layers of bubble wrap or similar material to ensure the product is safe during shipping. The box should be clearly labeled with the product name, weight, and shipping address.

For shipping, the Eddy Current Testing Equipment should be sent via reliable courier service, such as FedEx, UPS, or DHL. A tracking number should be provided once the product has been shipped.

FAQ:

- Q: What is the Brand Name of the Eddy Current Testing Equipment?

- A: The Brand Name is HUATEC.

- Q: What is the Model Number of the Eddy Current Testing Equipment?

- A: The Model Number is HEF-C35RFT.

- Q: Where is the Eddy Current Testing Equipment made?

- A: The Eddy Current Testing Equipment is made in China.

- Q: Does the Eddy Current Testing Equipment meet CE requirements?

- A: Yes, the Eddy Current Testing Equipment has a CE certification.

- Q: What is the minimum order quantity for the Eddy Current Testing Equipment?

- A: The minimum order quantity is 1pc.

- Q: How is the Eddy Current Testing Equipment packaged?

- A: The Eddy Current Testing Equipment is packaged in standard cartons.

- Q: How long does it take to deliver the Eddy Current Testing Equipment?

- A: It takes 5 days to deliver the Eddy Current Testing Equipment.

- Q: What payment terms are accepted for the Eddy Current Testing Equipment?

- A: Payment terms accepted are T/T and L/C.

- Q: How many Eddy Current Testing Equipments can be supplied per month?

- A: 100pcs of Eddy Current Testing Equipment can be supplied per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!