Heat Exchanger And Boiler Tube With Tube Sheet Mapping Eddy Current Detector

HEF-C35RFT eddy current instrument with remote field technology option is a new generation eddy current instrument. HEF-C35RFT with full-digital, multi-frequency, multi-channel is a versatile system offering a comprehensive array of electromagnetic testing techniques available on a single instrument HEF-C35RFT can be used to accurately and efficiently inspect both non-ferromagnetic and ferromagnetic tubing materials for flaws such as pitting corrosion vibrations wear steam erosion and cracking.

HEF-C35RFT combines the advanced testing capabilities of the HEF-C35RFT with a highly sensitive remote field technology option, makes the instrument an ideal solution for a broad range of tubing applications in the petroleum chemical and power generation industries. Where inspection of both non-ferromagnetic and ferromagnetic materials is required. In contrast to other ferromagnetic tubing inspection, the HEF-C35RFT provides not only a more complete --100% coverage with inner and outer surface discontinuity detection, but also thickness measurement -- in a fraction of the time.

Features And Specifications

Frequencies & Channels

●Own all of the function of HEF-C35++

●2 independently-selectable frequencies

●Frequency range from 1Hz to4MHz

●4 independently channels

●Three signal mixing capabilities

Gain Adjustment

●Adjustable gain from 0dB to 48dB in 0.5dB steps.

Phase

Independent vertical to horizontal display scaling ratio adjustable from 0.1 to 10

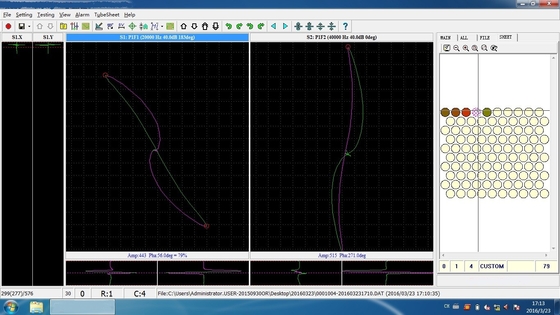

●A-scan and C-scan displays

●Delay erase display mode

●All instrument settings are shown on the display.

Alarm

●Audio, visual and logic output alarms

●Special alarm areas adjustable from 1 to 8

●Alarm area is provided for each display window of impedance plane

●Alarm area size and positioning are independently adjustable

●360 degrees phase shift can be varied in steps of 1

degree, the impedance plane can be rotated during

modification for ease of operation.

Colored Real-Time Display

●Colored real-time display of x-y impedance plane and/or strip chart signals.

●Alarm can be set to trigger either inside or outside the gated area

Filter & Others

●Digital filters

●Fast electronic balancing

●Adjustable sample rate.

Inputs

●Four connectors are provided for differential, absolute and reflection type probes. The connectors are designed to operate with most manufacturer’s probes.

●Other connects are provided for rotating probe.

Outputs

●Eight analog outputs

●Print data to Epson series

Memory Store & Recall

●Stores test setups

●Stores screen images

Easy to learn & Easy To Operate

●All parameter settings and configurations are done from the keyboard and can be individually stored and retrieved from hard or flexible disk.

●Friendly controls are directly accessible

Technical parameter

| Battery |

Lithium battery, long working time of 10 hours after one time charge |

| Channel |

2 channels |

| Frequency |

2 frequencies per channel with 64Hz-5MHz for ECT,5Hz-5KHz for RFT |

| Mixing Unit |

mixing unit to suppress noise signal at a constant frequency |

| Tube Sheet Mapping |

Tube sheet mapping draws according to real tube layout,and testing result is marked in different colors |

| Calibration |

Calibration on known flaws and automatic generation of calibration curve. Calibration data can be saved and simply called up when needed |

| Probe Type |

Differential, absolute,DP, encircling coil, pencil,flat,sector, array etc. |

| Screen Display |

Real-time strip chart,impedance plane ,tube sheet display |

| Report |

Automatic generation of report in different format |

| Alarm Output |

One hardware alarm output with triode OC gate |

| Gain |

0-90 dB in o.5 dB steps |

| Phase |

0-359 in 0.1steps |

| Gain Ratio (Y/ |

0.1-10 |

| Impedance Display Mode |

Point, Line, Auto |

| Filter |

High pass:0-500Hz Low pass:10-10000 Hz Digital1-100 |

| Drive Voltage Level |

1-8 levels |

| Background Coordinate |

Rectangular coordinate, polar coordinate |

| Power Supply |

Built-in lithium battery (14.8V,5.7AH) |

| Standards |

ASTM,JB/T4730.6-2005,DLT 883-2004 etc. |

| Balance |

Fast digital/analog electronic balance |

| Language |

English and Chinese |

| Operating Temperature |

-20C to 55C |

| Instrument Dimensions |

2.0kg; 290mm x 210mm x 42.5mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!