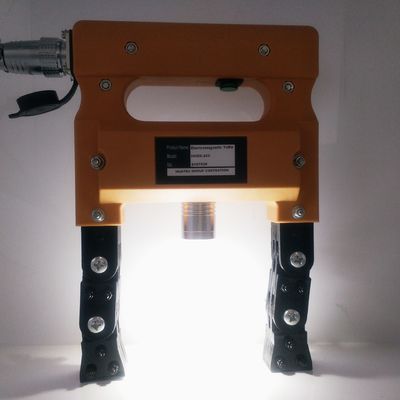

Built-In White Lamp Water-Proof 1 Minute Duty 220V AC Magnetic Yoke Mag Particle Testing Equipment

General

HUATEC Group is well-known brand in exporting and manufacturing of Magnetic Particle Testing Unit to overseas markets. This series of products are mainly used for the ferromagnetic material, weld and mechanical components of the magnetic particle testing. Probes using high-quality silicon steel, metallurgy and low loss ratio, adjustable magnetic pole head and the whole plastic shell such programs, which product has novel design, strong suction, voltage wide, multi-functional, and generalization characteristics. According to technical conditions, by using the voltage and control requirements to make series of products classify supply.This method enables to easily and rapidly detect surface flaw of forged products or welding, part, etc

Features

• Can achieve the best inspection effciency by HCDX-220

• Can form a strong manetic field with a VAC or DC type

• Can apply dry, wet and fluorescent magnetic particles inspection (MPI)

• Excellent durability by using a molding type of rubber material with strong water-proof, shock resistance

• Can test various objects to be tested by connecting middle poles

Main Parameter

| Product Name |

Handy Yoke Flaw Detector |

| Type |

HCDX-220 |

| Rating Voltage |

AC220V 50 |

| Magnetization kind |

Communion magnetization |

| Flat pole head suction |

Above 6Kg |

| U shape head sensitivity |

Use No.2 Magnetic indicator test, magnetic marks show clear |

| Magnetic head polar distance |

10-200mm adjustable |

| Size and weight |

170×150×50mm 2.5Kg |

| Power |

Single-phase 220V-240V |

| Mostly use |

For the flat weld, fillet weld, special Weld Inspection |

| Socket type |

P20J6A |

| Button switches line No. |

2,3 |

Standard accessories

1. Handy Yoke Flaw Detector HCDX-220 1pc

2. Power cable 1pc

3. Operation Instruction 1pc

4. Quality certificate 1pc

Principles of Magnetic Particle Testing

When the material or part under test is magnetized, discontinuities which lie in a direction generally transverse to the direction of the magnetic field will cause a leakage field to be formed at and above the surface of the part.

The presence of this leakage field and therfore the presence of the discontinuity is detected by the use of finely divided ferromagnetic particles applied over the surface, some of these particles being geared and held by the leakage field.

The magnetically held collection of particles forms an outline of the discontinuity and indicates its location, size, shape and extent.

Note

1, There should plus a small amount of lubrication on the pin joints before use.

2, Pressing the switch only after probe pole head to maintain good contact with the workpiece, switch should be released in time after probe leave workpiece. Avoid overheating failures which caused by improper operation of equipment.

3, HCDX-220 type power cable, such as configuration leakage protection plug, leakage protection function of plug should be checked if it normal before using.

4, When the user configuring HCDX-220 probe with main unit which from other manufacturers, should check the compatibility of the voltage and wiring

5, Lead section which connected to probe should not less than 0.75 square mm

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!