ASTM E165 NDT Cracked Aluminum Test Blocks Aluminum Alloy YM-A Dye Penetrant Testing

NDT Cracked Aluminum Test Blocks

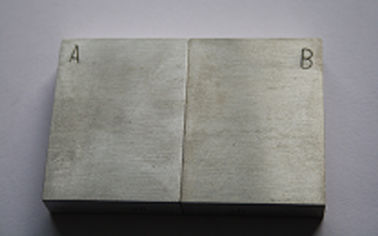

Cracked Aluminum Test Blocks compare sensitivity of different penetrants or sensitivity of new and used penetrants. This is done by processing one half of the block with used penetrant and the other half with fresh penetrant. It is manufactured to meet the ASME Boiler Pressure Code, Section V & III, and MIL-I-23135-C. The cracked aluminum block is made from 2024 aluminum and is 3” x 2” x 3/8” thick. A 1/8" wide groove separates the blocks two sides to facilitate side-by-side penetrant comparison.

It can be supplied with a Material Certification Form stating that the block meets:

- ASME Boiler Vessel Code 1992 Edition, Section V Nondestructive Examination, Article 6,

- Paragraph T-6-48.2 and 193 Addenda Paragraph T-653.2.

Aluminum alloy test block is composed of two parts with the same size after the same test block is cut open, and marked with the same serial number, respectively marked with A, B mark, A, B test block should have A fine relative weighing crack pattern. Other requirements of aluminum alloy test blocks shall be in accordance with the relevant provisions of JB/T 9213.

Aluminum alloy test block is mainly used in the following two situations:

A) Under normal use, check whether the penetration detection agent can meet the requirements, and compare the advantages and disadvantages of the two penetration detection agents;

B) Identification of penetrant detection methods for use at non-standard temperatures.

Model:YM-A (type A)

Through the physical and chemical test type A block material for LY12 aluminum alloy for materials, the chemical components conform to the provisions of ASTM,GB/T3190

By means of a micrometer measurement block length is 76 + 0.1 ㎜, and the width fifty + / - 0.1 ㎜, thick and ± 1 ㎜. Cut along the length center evenly divided into two pieces, and in block A and B and unity Numbers, block length orientation and plate rolling direction. Milling, grinding the surface roughness after treatment for Ra = 1.2 u m - 2.5 u m.

Color: Visual its color is silvery white.

Oxidizing property :In -55 ℃ ~ 200 ℃ - store between three years not metamorphism, no oxidation,

Crack: In the same Numbers of the A and B block with dye penetrant inspection method measured random crack 3 μ m, 3 μ m ~ 5 μ m and more than 5 μ m open crack on one side not less than four, and there are two above width is not more than 3 μ m open crack. Block A and B on the surface crack distribution is similar.

ASTME165 standard

| inspection item |

Test method and condition and requirement |

Check Result |

| Block Material |

Through the physical and chemical test type A block material for LY12 aluminum alloy for materials, the chemical components conform to the provisions of ASTM,GB/T3190. |

pass

|

|

Form and dimensions

|

By means of a micrometer measurement block length is 76 + 0.1 ㎜, and the width fifty + / - 0.1 ㎜, thick and ± 1 ㎜. Cut along the length center evenly divided into two pieces, and in block A and B and unity Numbers, block length orientation and plate rolling direction. Milling, grinding the surface roughness after treatment for Ra = 1.2 u m - 2.5 u m. |

pass

|

| Colour |

Visual its color is silvery white. |

pass |

| Oxidizing property |

In -55 ℃ ~ 200 ℃ - store between three years not metamorphism, no oxidation, colour and lustre is silver |

pass |

| Crack |

In the same Numbers of the A and B block with dye penetrant inspection method measured random crack 3 μ m, 3 μ m ~ 5 μ m and more than 5 μ m open crack on one side not less than four, and there are two above width is not more than 3 μ m open crack. Block A and B on the surface crack distribution is similar. |

pass |

Standard delivery:

YM-A block 1 set

Calibration certificate 1 pc

Case 1 pc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!