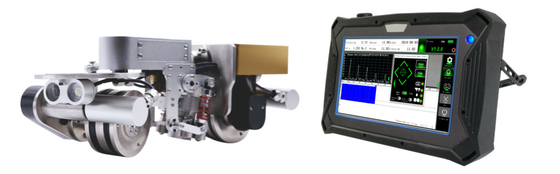

EMAT Magnetic Creep Magnetic Crawler Corrosion Thickness Measurement Tester

HUATEC Magnetic Crawler Corrosion Thickness Measurement System

- Configuration

| Item |

Name |

Unit |

Quantity |

Remark |

|

| 1 |

Test host(PC and software ) |

set |

1 |

|

|

| 2 |

HUATEC TG-M70 two-wheel magnetic crawler (Video and Thickness measurement module included) |

set |

1 |

|

|

| 3 |

Test control cable |

meter |

25 |

|

|

| 4 |

Safety rope drop preventer |

meter |

25 |

Optional |

|

| 5 |

Operation manual |

Pc |

1 |

|

|

| 6 |

Calibration certificate |

pc |

1 |

|

|

| |

|

|

- Brief introduction

This system does not need scaffolding, no need to polish the antiseptic layer, without any coupling agent. It can realize rapid detection of high altitude wall thickness corrosion through remote control system.

- Using the rare-earth high-strength permanent magnet wheel, even if there is an unexpected power failure, it will not fall from the detected surface. It can perform horizontal, vertical and inverted multi-attitude motions on the surface of ferromagnetic components.

- Install electromagnetic ultrasonic thickness probe for rapid screening and positioning against wall erosion

- Accurate scanning the area to test the thickness corrosion.

- Matching A scan and B scan display

- Equipped with video camera, can timely observe the video situation of the inspected surface.

- The remote control system to control the scanning direction, and it can be preset scanning direction.

- Two-wheel Magnetic crawler characters

Two-wheel magnetic crawler is an advanced instrument that can carry a variety of non-destructive testing equipment. At present, it has accumulated a large number of on-site settlement experiences in many fields such as petrochemicals, pot special inspections, and electric power. it can carry electromagnetic ultrasound in the bottom of the pipe, elbow or three links and other corrosion, erosion more serious areas to do inspection or B scanning thickness measurement, the industry field called pipe corrosion detection experts

Two-wheel magnetic crawler has the following characteristics: compact structure, high flexibility, magnetic suction, high control precision, advanced detection technology, compatible video detection, and unique probe lifting mechanism. For the automatic detection of corrosion of pipes, containers and plates

1) Compact structure and high flexibility

The compact and exquisite design allows it to easily perform corrosion detection for various types of ferromagnetic pipes and vessels. Magnetic rounds are 350mm (length)×140mm (width) × 130mm(height) and weighsless than 5.5kg. The unique two-wheel structure makes it possible to walk freely on pipes with a minimum of 100mm. The minimum turning radius is 400mm and the elbow with a minimum bending radius of 100mm can be easily passed. Therefore, the scope of two-wheel magnetic crawling movement and scanning has been greatly expanded.

2) Magnetic suction super

In terms of design, uses magnetic rare earth magnets to make high-strength permanent magnets in two rounds of magnetic climbs. Even if an accidental power failure occurs, there is no danger of the vehicle body falling from the detected surface. Therefore, two-wheel magnetic crawler can safely perform horizontal, vertical, and inverted posture scanning. The maximum vertical load of two-wheel magnetic crawler is 5kg, which means it will not affect any vertical motion when dragging 5kg weight.

3) High control accuracy

Two-wheel magnetic crawler speed is 0-6m/minute and can forward at a constant speed, by the precision encoder can achieve the function of setting the detection gap, can better achieve the user's detection needs. For example, the customer needs to perform a gap detection process every 50mm at one point in the back of the elbow: the controller can be programmed, and thetwo-wheel magnetic climb can be operated and inspected every 50mm. Improve the efficiency and accuracy of detection.

4) Advanced detection technology

Traditionally, piezoelectric thickness is used in the traditional thickness measurement, and it brings certain difficulty and strength to the inspection personnel in many fields in terms of its detection process. The manual inspection method of piezoelectric ultrasonic thickness gauge has the following disadvantages: (1) The paint layer or oxide layer on the surface of the workpiece needs to be polished, and the surface needs to be restored after the test is completed. The efficiency is extremely low; (2) The traditional ultrasonic must be coated with a coupling agent, which is very harsh on site conditions. (3) When working at a high site, a fixed platform must be built, which is costly and time-consuming; (4) It is difficult to perform in-service testing at high temperatures.

Using the advanced automatic crawling (electromagnetic ultrasonic) wall thickness corrosion detection system, the above-mentioned tedious problems will be solved, and the detection accuracy is comparable with the traditional piezoelectric ultrasonic. No need to build scaffolding, no need to polish the anti-corrosion layer, without any coupling agent, through the remote control on the ground, to achieve high-speed pipe wall corrosion rapid positioning screening and accurate measurement of dense scanning. While ensuring the detection accuracy, it greatly improves the detection efficiency and reduces the detection cost.

-

The detection position and detection route of high-altitude components can be real-time monitored and adjusted on the ground by using the two-wheel magnetic-climbing integrated forward and back double camera to ensure the controllability of the scanning track.

6) The two-wheel magnetic crawler is inevitably confronted with mechanical actions that require probe lift when performing corrosion point detection or B-scan inspection. When measuring the thickness of the point, the measurement needs to be performed at the same specified point. The data of each point is obtained when the probe lands on the surface to be measured. Therefore, the function of the probe can be lifted to achieve the most accurate point. The thickness value. When performing a B-scan on the object to be measured, although the probe is close to the surface, if the remaining height of the weld is large, the probe needs to be lifted and straddled. Therefore, the lifting and lowering function of the probe is also very important.

- Electromagnetic ultrasonic thickness measurement unit

Electromagnetic ultrasonic EMAT and traditional piezoelectric ultrasound belong to the category of ultrasound. Their essential difference lies in the difference of transducers. Piezoelectric ultrasonic transducers rely on the piezoelectric effect of a piezoelectric wafer to emit and receive ultrasonic waves, while EMATs rely on electromagnetic effects (magnetostrictive force, Lorentz force) to transmit and receive ultrasonic waves, and its energy conversion is in the skin layer directly on the surface of the workpiece. The traditional piezoelectric ultrasonic testing has a high requirement on the finish of the workpiece surface. Electromagnetic ultrasonic testing has a low requirement on the surface of the workpiece, allowing the surface of the workpiece to have paint, coating, and unevenness. Relative to conventional ultrasound. Electromagnetic ultrasound has the following advantages

- Non-contact detection, no coupling agent (lift up to about 4mm)

- The requirements for the surface are not high, the surface roughness can be detected, with oxide scale, coating, coating and other workpieces

- Fast detection

Piezoelectric ultrasonic EMAT

Crystal Magnet

Coupling agent Electromagnetic coil

Vibration Eddy current Magnetic field

Ultrasonic Ultrasonic

EMAT

Traditional piezoelectric ultrasonic technology is especially suits for highspeed, online and automatic detection

EMAT technology is especially suits for high temperature environment

Technical comparison of traditional piezoelectric ultrasonic technology and EMAT technology in high speed and high temperature environment.

EMAT technology has been applied to manual, semi-automatic and fully automatic on-line non-destructive testing of various forgings, steel bars, steel plates, and steel pipes (including seamless steel pipes, oil casings, welded pipes, etc.) at room temperature and high temperature.

- Functional features

- ★The detection position and detection route of high-altitude components can be real-time monitored and adjusted on the ground by using the integrated forward and back double camera to ensure the controllability of the scanning track.

- No surface polishing, anti-corrosion coating and floating rust can be penetrated, and no need for coupling agent.

- ★Thickness measurement can penetrate up to 4mm thick surface corrosion, paint, corrosion and other coatings, the thickness of the metal objects displayed by the instrument does not need to consider the calculation of coating thickness.

- ★Non-perpendicularity (normality of transducer/probe relative to the object under test) up to ±25o, low verticality after placement of the probe

- ★With probe electric lifting mechanism, the probe can be raised when crossing obstacles such as welds and bulges, avoid being held back.

- ★The thickness measurement results can be displayed in digital value form, A-scan form, time-based B-scan image form, and distance-based (encoder) B-scan image form.

- ★Using expert intelligence algorithm, there are three thickness measurement modes: automatic mode, single gate manual mode (single peak method measurement), and dual gate manual mode (peak-peak method measurement). It greatly reduces the influence of human factors and simplifies the operation steps.

- Built-in database of shear wave velocity of basic materials, and can customize the shear wave velocity value

- Directly issue inspection record list and thickness value list to facilitate data analysis and processing.

- Technical parameters

- ★Detection control cable:25m

- ★The minimum radius of curvature on the surface of the object is measured: the longitudinal axis≥50mm, and the circumference≥125mm

- Thickness Measurement: Accuracy 0.04mm, Range 2~120 mm (Steel)

- ★Work clearance / lift off:≤4mm

- ★Measurement non-perpendicularity (normal to the transducer/probe relative to the object under test):±25o

- Excitation frequency: 3.0~5.0MHz,measuring speed:16~1 times/s

- Sound speed range:1000~9999 m/s, adjustment increment: 1 m/s

- Gate function: automatic gate, manual single gate, manual double gate

- Video monitoring: both the front and back vision dual cameras, dynamic and static pixels are 3 million /2304×1296

- Normal temperature magnetic probe: weak or less permanent magnets, the magnetic suction≤15N, circular Φ30× high 44mm, weight≤80g

- ★Crawl device body size and weight (approx.):L380×W130×H120mm,6kg

- Working temperature: -10~+50℃

- Measurement Analysis Software

- Simultaneous display of thickness, A, B scan results

- Directly issued a test record, ★ thickness value list, to facilitate data analysis and processing

- ★Compatible with Win7/10 (32/64 bit) operating system

A/B-scan results

(Multi-line B-scan) thickness value list

Test record

- Packing list

- Application scene

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!