Auto Gain DAC PAC Curve Gate Expansion Weld B Display Train Track Rail Ultrasound Flaw Detector

Main introduction

FD-9008HT rail weld ultrasonic flaw detector - portable, easy to use and reliable

The rail weld ultrasonic flaw detector specially made according to TB/T 2658.21-2007 Rail Weld Ultrasonic Flaw Detection Operation, a standard of the Ministry of Railways, can simultaneously connect various probes required for rail weld ultrasonic flaw detection, preset flaw detection parameters, on-site flaw detection, one button switch, fast and simple, excellent performance, and powerful functions. It is the first choice for rail weld ultrasonic flaw detection.

Main features

■ Easy to operate: an instrument tailored according to the requirements of the rail weld flaw detection process. It works in multiple channels and can detect different areas of the rail weld

It is necessary to replace the probe, change the setting parameters and switch the channel with one key to complete the detection of different areas of the weld rail head, rail web and rail bottom.

■ Small volume: it is the smallest in the rail weld flaw detector with 5.7 inch display.

■ Light weight: the weight of the whole machine including the battery is only 1.4kg.

■ Low power consumption: the battery can work continuously for more than 6 hours at most.

■ High performance: major technical indicators such as flaw detection sensitivity margin, vertical linearity, horizontal linearity, dynamic range, etc. are superior to relevant national standards.

■ Multi functions: USB interface, automatic gain control, DAC, gate expansion, screen copy, etc.

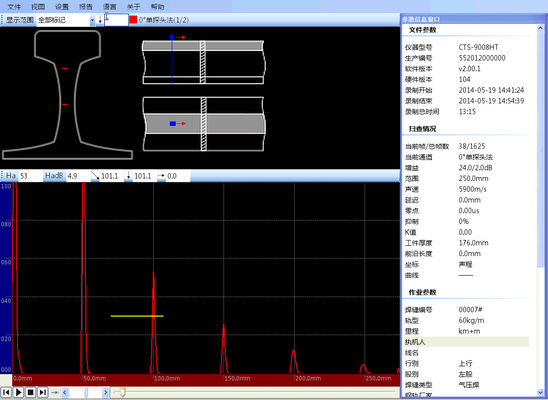

■ B display: it has the function of B display mark map of weld seam, which is used to automatically distribute the alarm signal on the I-shaped section of rail weld seam

Marking; The detection process has a schematic diagram of step prompts. The test steps and results are clear at a glance.

■ Short film recording: You can select the internal storage or U disk storage. The internal memory of the computer can be transferred to the USB flash disk. The upper computer software has short film file playback and Management functions.

• The maximum sampling rate is 240MHz, and the measurement resolution is 0.1mm.

• The operating frequency range is 0.5 ~ 8MHz, and the sensitivity margin is up to 65dB.

· Wizard type channel selection menu, combined with the schematic diagram of detection steps, makes the detection operation process simple and fast.

· Humanized flaw detection report, quick marking of defect nature, damage location, processing technology, etc., and intuitive and clear later analysis.

• 20 ~ 500Hz has 10 adjustable pulse repetition rates to avoid reverberation signals during flaw detection.

• The function of weld B display marking map is to automatically mark or manually mark the distribution of alarm signals on the rail weld section.

• Serial and double K scanning based on encoder, one-time scanning imaging of weld section defect alarm diagram.

• Cooperate with peak echo and image freezing functions to quickly determine the highest wave of defects, and the flaw detection is more efficient.

DAC curve, combined with echo comparison function, makes echo quantification at different distances and different amplitudes easier.

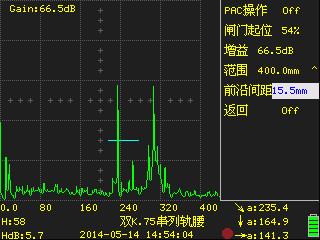

Based on the PAC curve function scanned by the encoder, the amplitude of defects of the same size in different depths is automatically adjusted, and the scanning image effect is closer to the actual.

• The 5.7 ″ imported color TFT display screen with wide viewing angle, high brightness and high definition has a clear view of the details.

• Different color schemes meet the needs of different use scenarios and habits.

| Number |

Interface |

Detection position |

| 1 |

Single K2.5 |

Scan the rail head from the rail head tread or side of the rail head (in case of single K2.5 rail head top channel), and scan the rail bottom from the rail bottom slope (in case of single K2.5 rail foot channel) |

| 2 |

Single K1 |

Scan from the rail head tread surface to the rail head, rail web and rail bottom (in case of single K1 rail head top channel) |

| 3 |

Single 0° |

Scan from the rail head tread surface to the rail head, rail web and rail bottom (in case of single 0 ° rail head top channel) |

| 4 |

Double 70° |

The single double 70 ° probe is used to scan the rail head from the rail head tread or side of the rail head (in case of double 70 ° rail head channel); This pair of sockets is also used to define the side of double K1 rail head, and K-scan the rail head (when the side channel of double K1 rail head is used) |

| 5 |

Double K0.75 |

Tandem scanning from the rail head tread surface to the rail waist (when dual K0.75 tandem rail waist channel) |

| 6 |

Double K1 |

K-scan the rail bottom from the side of the rail bottom (in case of double K1 rail bottom side channel) |

Application :

Install the scanning frame to a proper position on both sides of the weld. Adjust the probe moving knob of the scanning frame to move the tandem probes one after the other in the opposite direction, and scan up and down along the weld according to the scanning diagram.

| Single K2.5 angle probe |

Single K1 angle probe |

|

|

| Using a single K2.5 angle probe, make a DAC curve for No. 1~5 cross holes in Zone B of GHT-5 test block, and scan the rail tread and side with a single wave. The figure shows the echo of defects in the rail head. |

Single K1 angle probe is used to scan the rail waist forward and backward from the rail tread with a single wave. The figure shows the echo of defects at the rail bottom. |

| Tandem dual K0.75 angle probe (A-scan) |

Tandem dual K0.75 angle probe (A+B scanning) |

|

|

| A pair of K0.75 angle probes placed in tandem are used to scan the rail waist with the scanning frame. The figure shows the echo of hole 5 on the GHT-la test block. |

The I-shaped area shown in the figure is the B-scan of defects in holes 1~5 on the GHT-la test block. |

| Guided channel selection |

Editing of flaw detection operation parameters |

| The guided channel selection interface makes the detection process clear at a glance. With the channel shortcut key, the operation is efficient and flexible. |

The editing of flaw detection operation parameters can quickly mark the defect nature, damage location, processing technology and other parameters, facilitating the analysis and evaluation of flaw detection results in the later stage. |

| Record playback during scanning |

|

|

|

| Scan the whole process records. It can play back, query and generate reports on the upper computer. |

|

Technical indicators

| Item |

Unit |

Technical data |

| Vertical linearity error |

% |

≤3 |

| Attenuator error |

dB |

Every 12 ±1 |

| Dynamic range |

dB |

≥32 |

| Electrical noise level |

% |

≤10(frequency band:1~5MHz) |

| Flaw detection sensitivity margin |

dB |

≥65(2.5Z20N probe) |

| Sheet resolution |

mm |

≤3(5C10N probe) |

| Far-field resolution |

dB |

≥26 |

| Horizontal linearity error |

% |

≤0.5 |

| Detection range |

mm |

0 ~ 13000(Steel longitudinal wave) |

| Pulse shift range |

mm |

-10 ~ 1000 (Steel longitudinal wave) |

| Material Sound velocity |

m/s |

400 ~ 15000 |

| Probe zero range |

µs |

0 ~ 200 |

| Gain adjustment |

dB |

Range:0 ~ 110; Adjusting gear:0.5 / 2 / 6 / 12 |

| Working frequency |

MHz |

1 ~5 / 0.5 ~8 |

| Launch mode |

|

Weak/strong |

| Damping |

|

Low/High |

| Inhibition |

% |

0 ~ 80 |

| Detection mode |

|

Negative detection/positive detection/bidirectional detection/filtering/RF |

| Repetition frequency |

Hz |

Adjustable in 10 grades (20~500Hz adjustable, but limited by detection range, material sound velocity, pulse shift, probe zero point, etc.) |

| Storage |

|

500 sets of data sets, including instrument settings, flaw detection status, echo patterns, etc |

| Video recording |

|

Short film recording function (including A-scan and weld seam marking map). Short film playback of upper computer. Internal saving or USB flash disk saving can be selected. |

| Marking diagram of weld B |

|

Identification mark used for distribution of alarm signals on rail weld section. This includes automatic and manual marking. |

| Automatic gain function |

|

Automatically adjust the echo amplitude in the gate to the specified amplitude

Amplitude setting:40% / 50% / 60% / 70% / 80% / 90% / 100%

|

| Gate |

|

1 measuring alarm gate

Gate mode: off/wave inlet/wave loss

Gate lifting: 0~109%

Gate width: 1~109%

Gate level: 10~90%

|

| Alarm |

|

off / on,Enable and disable buzzer alarm sound |

| Automatic correction function |

|

Used to correct the material sound velocity and probe zero point

Correction mode: sound speed+zero point

|

| Angle measurement function |

|

Used to measure probe angle |

| DAC function |

|

Used to make, set up, and apply DAC curves |

| PAC function |

|

In tandem/K-scan based on encoder, the same equivalent signal at different positions of the weld is compensated for gain, so that the reflected signal of the same equivalent at each position is close to the same detection sensitivity. |

| Transfer function |

|

Transfer the internal data set of the instrument to the USB disk through the USB interface |

| Data storage |

|

Built in SD card(4G) |

| Display |

|

5.7 "High brightness TFT LCD, 320 × 240 pixels |

| Return to factory setting function |

|

Restore the instrument settings to the factory state |

| Power Supply |

|

Adapter or lithium battery

Adapter: AC input 100V~240V, DC output: DC 12V

Battery:6.4V ~ 8.4V

|

| Battery working time |

h |

≥6(Related to the brightness of background light) |

| working temperature |

℃ |

-20 ~ +50 |

| Weight |

kg |

About 1.4 (including battery) |

| Size |

mm |

152 × 240 × 68 (Width × high × Deep) |

Optional scanning frame HRWS-C-K0.75

HRWS-C-K0.75 rail weld scanning frame is suitable for ultrasonic tandem flaw detection scanning of rail waist welds (including thermit welding, gas pressure welding and flash welding). The main features of the product are small size, light weight, easy to carry, simple operation and practical on site. It is an essential scanning device for rail weld flaw detection.

Standard Package

Portable Ultrasonic Flaw Detector FD-2008HT

Straight Beam Transducer

Angle Beam Transducer

Connect Cable for the transducer (BNC-LEMO 00,or optional LEMO 01-LEMO 00)

Rechargeable Li-Ion Battery Package

Power supply/charger unit

Operating Manual in English

Calibration certificate

Optional Accessories

Straight probe (5MHZ-ф20)

Straight probe (2.5MHZ-ф20)

Straight probe (2.25MHZ-ф20)

Straight probe (1MHZ-ф20)

Angle probe (4MHZ-45degree, 8*9mm)

Angle probe (4MHZ-60degree, 8*9mm)

Angle probe (4MHZ-70degree, 8*9mm)

Angle probe (4MHZ-80degree, 8*9mm)

Angle probe (2MHZ-45degree, 8*9mm)

Angle probe (2MHZ-60degree, 8*9mm)

Angle probe (2MHZ-70degree, 8*9mm)

Angle probe (2MHZ-80degree, 8*9mm)

Probe T/R (5MHz-ф20mm, focus 15mm)

Probe T/R (2.5MHz-ф20mm, focus 15mm)

Connection cable to probe (BNC-BNC)

Connection cable to probe (BNC-Lemo 00)

Connection cable to probe (Lemo 01-BNC)

Connection cable to probe (Lemo 01-Lemo 00)

Lithium ion battery

Power adapter (4A/9V)

Power Cable

Test block V1

Test block V2

Test blocks DAC, ASME etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!