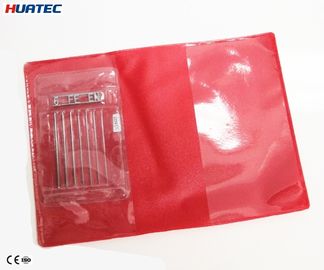

EN 462-1 Wire Type were introduced as a EUROPEAN STANDARD to supersede the German Standards

(DIN 54.109) and the British Standards Institute (BS3971:1980 type 1) Image Quality Indicators. Each

indicator consists of a series of seven parallel wires of different thichkness mounted and encapsulated

between two thin sheets of transparent, flexible PVC. A lead monogram indicates the number of the thickest

wire, the material and the EN symbol.

Wire Diameters:

Indicator Sizes:

There are four sizes of EN Image Quality Indicators.

Size 1 – contains wire numbers 1 to 7 and used for material thicknesses in

the range of 40 t 160mm

Size 6 – contains wire numbers 6 to 12 and used for material thicknesses in

the range of 12.5 to 50mm

Size 10 – contains wire numbers 10 to 16 and used for material thicknesses

in the range of 5 to 20mm

Size 13 – contains wire numbers 13 to 19 and used for material thicknesses

in the range 2.5 to 10mm

All sizes are available in Steel(Fe), Aluminium(Al), and Stainless Steel(SS). Copper(Cu), Zirconium(ZR) Image

Quality Indicators are only available in sizes 6 and 10. Nickel(Ni) Image Quality Indicators are only available in

sizes 6, 10 and 13.

As an illustration the identification (i.e. lead monogram) for, say Size 10 (Wire numbers 10 to 16) in steel(Fe)

would be 10 FE EN.

DIN 54 109 Wire Type Image Quality Indicators are similar to the EN 462-1

I.Q.I’s, the wire diameters are the same, and there are the same wire

numbers in each size of indicator. The only difference being that the lead

monogram reads DIN rather than EN.

Example:

Size 6Wire numbers 6 to 12) in Stainless Steel(SS) would be 6 DIN SS.

EN 462-2 Stepwedge/Hole Type Penetrameters

Stepwedge in shape and available in four Model Numbers H5, H9 and H13 in Steel.

ASTM E747 Wire Type Penetrameters consists of a series of six parallel wires of different thicknesses,

encapsulated between two thin sheets of transparent, flexible PVC. Lead characters identify the thickness of

the thickest wire, and the material group(1-FE, 01-Ti, 02-Al, 03-Mg, 3-Ni, 4-Cu). The letters ASTM are also

included.

ASTM SE 1025 Plate Penetrameters are normally used to conform with

the American Inspection Standards. They are rectangular plates, 2% in

thichness of the specimen and of material radiographically similar to the

specimen. Each plate has three holes drilled equal in diameter to 1X, 2X,

and 4X the plate penetrameter thickness. The minimum thickness of

Plate type penetrameter is 0.010’’. For Penetrameters greater than

0.180’’, these are supplied in disc form, the outside diameter is 4X, with 2

holes 1X & 2X the thickness of the Penetrameter.

The chart below gives Plate Penetrameter Identification and thickness

and a guide as to which penetrameter to use for each material thickness.

PS: if you have any new products(outside this cataloge) about Radiography, which you want

to have them make to order, please let me know without any hesitation!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!