300KV Ceramic tube penetrant 40mm Directional Radiographic inspection machine

Trouble Shooting

If the unit get out of control in the states of exposure and aging, such as over-voltage, under-voltage, over-current and under-current,etc. voice will prompt,the system will turn off high voltage automatically and return to ready state,in the meantime corresponding protective indicator lamp will be on and indicate the type of troubles.Press"OFF"key for clearing the trouble after you confirm the trouble type, and then try it again.

When the tube head temperature is too high and overtemperature indicator (OV)is flashing, now all keys are unworkable,exposure can be taken again when the temperature return to normal and the unit return to ready state automatically.

If time stops and displays in confusions,power supply must be cut off immediately and check up the voltage,gas pressure of the generator,air humidity and cables connection,after informing it being normal, the machine can be turned on again.

XXG3005 Ceramic tube orientation/directional

Usage:

The HUATEC Flaw detector products have been widely used for nondestructive testing in spaceflight industry, welding engineering industry, shipbuilding industry, boiler pipe industry, petrochemical engineering industry, aircraft manufacturing, maintenance industry, automotive industry, defense industries, etc.

Main technical parameters

|

TYPE

|

XXG3005 |

| Max Penetration thickness Steel (A3) |

50mm |

| Focal Distance |

600mm |

| Exposure Time |

5min |

| Film Type |

TianJin Ⅲ |

Double lead foil Intensifying screen

|

0.03 |

| Darkroom Disposal |

20±2℃ |

| Development |

5minutes |

| Blackness |

1.5 |

| Input |

Voltage (V) |

220V±10% 50―60Hz |

| Capacity (KVA) |

2.0 |

| Output |

Tube voltage (KVP) |

150-300 |

| Tube current (mA) |

5 |

| Stability |

±1% |

|

X-RAY

Tube

|

Focus mm2 |

1.5×1.5 |

| Radiation Angle |

40±5° |

| Sensitivity |

k≤1.8% |

| Operation Mode |

Intermittent operation, Radiating time to cooling time is 1:1 |

|

X-Ray

Controller

|

Dimension |

270×270×140 |

| Weight |

9kg |

| Circuit Structure |

Micro-computer control ,Modular structure,Voice prompt |

|

X-RAY

Generator

|

Cooling |

Force air cooling |

| Insulation |

SF6 Gas Insulation |

| Working Pressure |

0.35Mpa-0.45Mpa |

| Dimension |

340×340×670 |

| Weight (kg) |

32kg |

| Working Temperature |

-10℃―+40℃ |

Working Principle

This machine is composed of intelligent controller-ray generator, power cable and connecting cable.

1.The controller will consist of the following sections:

Front Panel: LED display, status and failure indicator, touch keyboards (see the introduction of control panel)

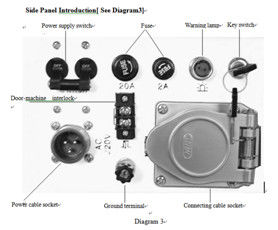

Side Panel: power cable socket and connecting cable socket, power switch,key switch, fuse socket, warning lamp and wire connecting terminal of door-machine interlock.

Internal Circuit: power circuit, rectifying circuit, filter circuit, inverter circuit, control circuit and other circuited.

2.The x-ray generator will consist of the following sections:

X-ray tube, High voltage transformer, Temperature relay, Gas pressure gauge and Cooling fan etc.

3.The schematic diagram of the complete machine:

Standard Delivery

| Directional glass X-ray tube |

1 Pcs |

|

| Generator |

1 Set |

|

| High voltage joins cable |

1 Pcs |

25 Meters |

| Controller |

1 Set |

|

| Power cable |

1 Pcs |

10 Meters |

| Grounding cable |

1 Pcs |

5 Meters |

| Accessories |

1 Set |

|

| (Including: alarm lamp,1 Pcs; lead letter, 1 box; Film dark cassettes 5 pcs; intensifying screen 5 pcs; Wire penetrameter (IQI) 1 set; fuse1 pc) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!