WRT Elevator Wire Rope Detector Steel Rope Wire Rope Internal External Flaw Detector

I. Product Overview

◆ can on-line test the wire rope internal and external broken wire, wear, corrosion, deformation, loose strands, jump wire, material changes and other defects.

◆ the test results can meet the standards of different industries and can be displayed in the form of the number of broken wires and the ratio of the broken wire area to the total broken wire area.

◆ computer USB interface for direct sampling, processing and analysis, with online sound and light alarm and real-time display results.

◆ sensor circular structure, circumferential surround, axial magnetization, magnetization of the wire rope to saturation state.

◆ The sensor adopts alloy aluminum shell, which is waterproof, dustproof, shockproof and moisture-proof.

◆ stable work, reliable performance, high detection accuracy, strong anti-interference performance, accurate data.

◆ software to adapt to Windows98/2000 / xp/Vista/windows7 various computer operating systems

◆ in accordance with the provisions of the national metrology law and the national production safety law, each instrument shall be inspected by the national metrology institute as a third party in accordance with the American standard ASTM1571, and the test report shall be issued to obtain the legal qualification.

◆ widely used in mining, ropeway, lifting equipment, elevator, port machinery, cable bridge and other fields.

2.Technical core and legal qualification

(1). Virtual instrument: infinite uncertainty of wire rope.Only by using virtual instrument technology, replacing traditional instrument with software, and using computer to directly sample, we can ensure no missed inspection and wrong judgment, just like watching a movie, scanning the whole process of wire rope, the results are accurate and repeatable.

(2). Three-determination instrument: according to the national standards for scrap of wire rope in different industries, this product applies electromagnetic qualitative, quantitative, positioning, online nondestructive testing of wire rope internal and external broken wire, rust, wear, metal sectional area change, loose strands, jumping wire, deformation, material abnormalities and other defects.

(3). Legal instruments: according to the provisions of the national metrology law and the national production safety law, each instrument is inspected by the national metrology institute according to the American standard of astm1571-2006 and GB/ t21387-2008 as a third party, and the test report is issued to obtain the legal qualification.

3.Technical indicators

Full range of wire rope diameter range can be detected: Φ 1.5-300 - mm (need to configure different series specifications sensor)

Relative speed between sensor and wire rope: 0.0 -- 6.0 m/s best: 0.3 -- 1.5 m/s

The best gap between sensor guide sleeve and wire rope is 2 -- 6 mm, and the allowable gap is 0 -- 15mm

Broken wire defect (LF) detection capability

Qualitative: single concentrated broken wire qualitative detection accuracy is 99.99%

Quantification: the number of broken roots in a single place allows one or one equivalent root to misjudge

More than 100 times of quantitative detection with single centralized root breakage without error, the accuracy rate is ≥92%

Quantitative rate of change of metal cross section (LMA)

Permissible error of detection sensitivity repeatability: ±0.055%

Permissible error of detection accuracy indication: ± 0.2%

Position (L) detection capability: detection length percentage error: ±0.2%

Power supply: computer battery power 5V

Sensor weight: commonly used specification < 10kg

Ambient temperature: -10℃~40℃ atmospheric pressure: 86~106Kpa relative humidity: ≤85%

4.System configuration and model

(1). Elevator wire rope diameter is 8-16mm

(2). The total model of wire rope computer flaw detector is E15/E20

| |

The serial number |

Content |

Qty. |

Comment |

|

The sensing

unit

|

1. |

E15 Excitation polymagnetic sampling sensor(Automatic distance positioning to form an encoder) |

1 |

8-16mm All kinds of elevator wire rope can be tested (single rope) |

| 2. |

E20 Excitation polymagnetic sampling sensor

(Automatic distance positioning to form an encoder)

|

1 |

8-16mm All kinds of elevator wire rope can be tested (multi-rope) |

|

conversion

unit

|

3. |

RADFDigital converter

(Online monitoring and real-time alarm)

|

1 |

The module is imported from USA |

| 4. |

8344 Signal switching |

1 |

|

| 5. |

USB Serial converter line |

1 |

|

|

To deal with

unit

|

6. |

V3.0 Version Processing package |

1 |

|

| 7. |

Laptop |

1 |

Including computer bag plus mouse |

| The attachment |

8. |

Standard packing case |

1 |

|

| 9. |

Safety line |

1 |

|

| 10. |

Issued by the national legal metrological institution

Third-party test report

|

1 |

The use of the instrument obtains legal qualification |

5. Specifications

Standards: GB/T21837-2008, ASTM E1571-2001 (Standard specification for electromagnetic examination of ferromagnetic steel wire rope), GB/T5972-2006/ISO 4309:90, GB8918—2006

Detecting range:Φ1.5—30 mm (choose different sensor)

Relative velocity between sensor and wire rope:0.0—6.0 m/s Best choice:0.3—1.5 m/s

Best gap between guide sleeve and wire rope: 2—6 mm,allowed gap:0—15mm

Output file type: Word files output

Alarm: Sound and light alarm

Broken wire rope location(LF)detection

Qualitative judgement accuracy: 99.99%

Quantitative assessment

Repeatability error of Sensitivity: ±0.055%

Display error: ±0.2%

Error of location detection,(L): ±0.2%

Power:5V computer power supply

WEIGHT OF SENSOR: < 10kg (Regular sensor)

Environment temp.-10℃~40℃

Air pressure:86~106Kpa

Relativity humidity:≤85%

The windows system of wire rope computer detector is the GB system renewal product which based on the DOS software theory and the real time display alarm guiding ideology utilizes Visual Basic6.0 the programming language foundation, carries on the compilation to become.

This system hardware part uses the domestic and foreign advanced magnetic sensor and the independent research and development sampling module unifies, through RS232 (or USB) main line driving, directly storage data in computer.

This system software part is in the wavelet transformation analysis foundation, in utilizing Visual Basic 6.0 programming language foundation, carries on the compilation to become. Achieve the functions such as data acquisition and control, data analysis, data display, data storage and so on. Increase the visible characteristic in the DOS software function, and by its unique tendency continuously to track the way, may continuously, the dynamic observed data signal and its the change situation, and the real time display obtained result and sends out the alarm; Software increased the automatic evaluation function; In the partial flaw demonstrated on increased cross section and the total sectional area percentage; Software and Windows are completely compatible, suits to user's inertia operation, uses the Word files form production examination report.

This system software may compatible wire rope computer detector DOS software sampling data format, and can analysis processing to it.

The windows system took an independent operating procedure and the safe examination system, can conveniently be suitable for each kind of modern computer, and completes a series of examinations procedure.

6. Systems Demand

6.1 Computers Hardware Disposition Demand:

Processor: Above Celeron 1.5GHZ

Memory: 128MB

Hard disk: 10G

Connection: RS232 or USB

Monitor: Above VGA

6.2 Software Environment Demand:

- This system supports the Windows XP, Windows 7, Linux etc operating system;

- Need install Microsoft office word platform.

6.3 System Disposition

| Magnetic sensor (including distance locator) |

A group |

| HUATEC HRD-150 real-time alarm apparatus |

One |

| Signal connection line |

One |

| RS232 transmission line (or USB to RS232 transformation line) |

One |

| windows special-purpose software package |

One |

| Computer |

One |

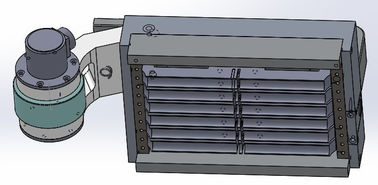

7. Sensor introduction

Magnetic sensor: The sensor is composed by displacement locator (Leading wheel, encoder), the magnetization installation and the sampling organization. After the system activated, the wire rope and it has the relative movement, then it can gather the signal.

Displacement locator: Leading wheel rotated a circle, the photoelectric encoder sends out the sampling instruction pulse, realizing equal space sampling.

Magnetization installation: When the wire rope and it has the relative movement, completes to the wire rope axial magnetization.

Sampling organization: When the wire rope and the sensor have the relative movement, the Hall element composed the sampling channel will transform the wire rope magnetic flux leakage change condition into the simulation voltage signal.

8. HUATEC real-time alarm apparatus

The HUATEC real-time alarm apparatus is a portable multi-purpose data acquisition, through the RS232 transmission line to send and save the converted data signal to the computer, make use of the computer CPU formidable function on-line and real-time processing analysis, according to the equivalent threshold value which will set in advance sends out the real-time alarm. One group to give the sensor power supply lithium battery group, the output is 5V. There is an addition charge port to be possible to supply the charge and the power switch.

Picture 2 Signal Sampling Wiring Diagram

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!