Integral Dual OLED Surface Roughness Measuring Instrument Portable Surface Roughness Testers SRT5030

Features

Dual OLED displays to suit your applications;

2 start keys ( the left key & the right key) to satisfy the different using habits;

Mobile app compatible to get the higher accuracy, convenient to be used in a small space

ARM processor to offer higher speed, low power consumption and fast accurate measurement.

Light weight of 150g, easy & convenient to use.

Measurement Principle

When measuring surface roughness of workpiece, the pickup is placed on the surface of the part and then tracing the surface at constant rate. The pickup acquires the surface roughness by the sharp stylus in pickup. The roughness causes displacement of pickup which results in change of inductive value of induction coils thus generate analogue signal which is in proportion to surface roughness at output end of phase-sensitive rectifier. This signal enters data collection system after amplification and level conversion. After that, those collected data are processed with digital filtering and parameter calculation by ARM processor and the measuring result can be read on LCD, printed through PC.

| Main Technical Specifications |

| Optional Parameter |

Ra, Rz, Rq, Rt |

| Measuring Range(μm) |

Ra, Rq: 0.05 ~ 10.0; Rz, Rt: 0.1 ~ 50 |

| Sampling Length(mm) |

0.25/ 0.80/ 2.5 |

| Evaluation Length(mm) |

1.25/ 4.0/ 5.0 |

| Running Length(mm) |

6 |

| Display Accuracy |

0.01μm |

| Display Deviation |

±(7-10)% |

| Display Repeatability |

<12% |

| Stylus Radius |

10 μm±1 μm |

| Static Contact Force |

≤ 0.016N |

| Force Change Rate |

≤ 800N/m |

| Sensor Lead Pressure |

≤ 0.5N |

| Battery |

3.7V Lithium Rechargeable battery |

| Dimensions in mm |

110×81×32 |

| Weight |

150g |

Standard Delivery

| Main Unit |

1 pc |

| calibration block |

1pc |

| Power adapter |

1pc |

| USB cable |

1 pc |

| User Manual |

1 pc |

| Calibration certificate |

1 pc |

Optional accessories:

Roughness Calibration Block Multi-engraved lines (Square Wave)

Made by optical glass, with high hardness, high accuracy standard roughness value, anti-scratch, has longer life than metal roughness block.

Meet standard GB/T19067.1-2003 and ISO5436-1:2000

Approximation: Ra=0.1um, 0.2um, 0.4um, 0.8um, 1.6um, 3.2um, 6.4um

Customized Value and Sine Wave available, welcome to inquire.

Roughness Calibration Block Single engraved lines

Made by optical glass, with high hardness, high accuracy standard roughness value, anti-scratch, has longer life than metal roughness block.

Meet standard GB/T19067.1-2003 and ISO5436-1:2000

Approximation: Ra=0.1um, 0.2um, 0.4um, 0.8um, 1.6um, 3.2um, 6.4um)

Customized Value available, welcome to inquire.

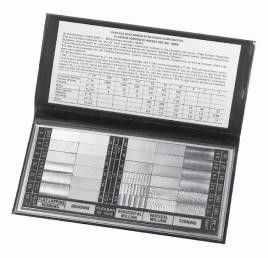

Roughness Comparator (30 pcs/set)

This set contains standards of the six most important machining methods in the prevalent "AA" values. These surface roughness is used to compare and determine the degree of the surface finish by comparision method and eye estimation or magnifying glass.The surface rough contast blocks is made of 45 super carbor steel except the GCr15 which is using to plat lapping the sample block. All 30 speciments are calibrated in u''AA (Arithmetical Average) and in the metric equivalents um Ra.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!