HUATEC-SUPER-3D X-ray digital direct imaging system

Portable X-ray 3D / 2D Imaging System

High-end quality, quality assurance

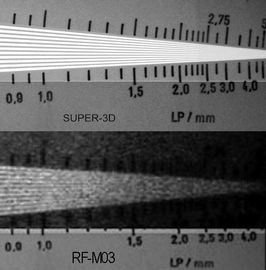

Upper left:The SUPER-3D resolution with standard "wire pair gauge" is 3.6 LP / mm.

Lower Right:For comparison, the lower left figure is the standard resolution of the standard X-ray imager, about 1.1 LP / mm.

From the top left, we can see SUPER-3D system with ultra-high definition.

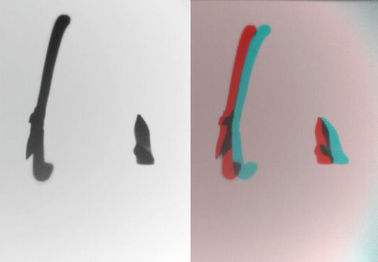

HUATEC-SUPER -3D see the objects hidden in heavy objects

Left: X-ray perspective image of a cylinder fire extinguisher. As the cylinder is very thick, can penetrate the cylinder X-ray is very weak.

Middle: SUPER-3D has 16,000 gray level, the darkest hundreds of gray-scale images to highlight, you can clearly see the fire extinguisher cylinder with circuit boards and metal objects, suspected homemade bombs.

Right: SUPER-3D "Transform", you can quickly display these hidden objects in the heavy objects, and retain the original outline image.

left:

SUPER-3D is used to detect high voltage transmission wire clamps.

Large image: the distribution of aluminum within the clip;

Small map: Adjust the display of the gray level, check the steel core into the steel anchor (the white area shows the steel core is not inserted in the end).

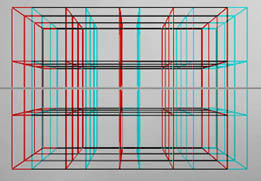

HUATEC-SUPER-3D 3D Imaging Effect

After the overlapping objects when 2D sytem, Can be seen 3D imaging it is more the clear!

Watch 3D images please wear red and green 3D glasses. (Letter to send) Looking at the paper print file, the 3D image may have some artifacts because the printer's color is different from the computer monitor. In the computer to see this information, 3D images there is no artifact.

(Left): objects placed in the direction of the ray

2D imaging may be difficult to identify;

(Right): in the 3D imaging of the image, the image on the vivid.

HUATEC-SUPER -3D display 3D images, you can attach a 3D grid, to help you 3D objects in the field of 3D positioning. And can display the selected part in real 1: 1 ratio.

HUATEC-SUPER-3D

Gd2O2S, iRay

Detector window: 350mm × 430mm

Pixel count: ≥2448×2984 (2288×2800)

Gray level: 16-bit (14-bit)

Resolution: 3.4 LP / mm (2.8 LP / mm)

- HHD X-ray Flat Panel Detector

- American Original High-reliability X-ray generator

The American original highly reliable XR series X-ray generator is adopted and users are able to select according to their own needs.

XR200 of high luminance (Code: Type B)

150kV, 3 milliroentgens per pulse, 5.5kg, penetrating power: Steel 12mm.

XRS-3 of high penetrating power (Code: Type C)

270kV, 3 milliroentgens per pulse, 5.7kg, penetrating power: Steel 25mm.

Rear view Front view

Battery pack of flat panel detector, battery indicator;

Network interface;

On-site monitoring TV;

Gigabit cable connection;

WIFI access.

300M

AP WiFi

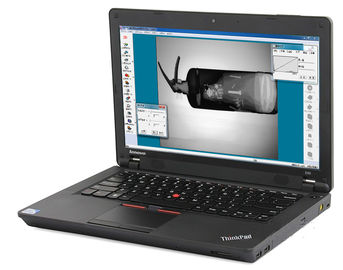

- Highly reliable notebook computer; HUATEC software of an advanced transfer function; easy to operate

Notebook computer ThinkPad with high reliability and a highly disk is adopted reliable hard. A wireless relay can be added during wireless monitoring and control:

Notebook computer ThinkPad with high reliability and a highly disk is adopted reliable hard. A wireless relay can be added during wireless monitoring and control:

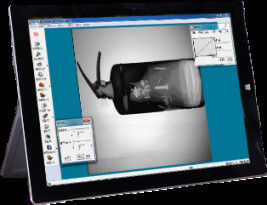

Optional Pad can be chosen

Loading with Advanced HUATEC-SUPER-3D software, fast operation.

| Standard delivery of HUATEC-SUPER-2D |

Optinal accessories for HUATEC-SUPER-2D |

| HHD X-ray Flat Panel Detector |

1pc |

|

| X-ray machine XR200 high luminance (Code: Type B) 150KV |

1pc |

X-ray machine XRS-3 of high penetrating power (Code: Type C) |

| HUATEC-SUPER-2D Network Interface Box |

1pc |

|

| Connection cable |

1pc |

| Highly reliable notebook computer |

1pc |

|

| 300M AP WiFi Module |

1pc |

|

| Software (Installed) |

1pc |

|

| Standard delivery of HUATEC-SUPER-3D |

Optinal accessories of

HUATEC-SUPER-3D

|

| HHD X-ray Flat Panel Detector |

1pc |

|

| X-ray machine XR200 high luminance (Code: Type B) 150KV |

1pc |

X-ray machine XRS-3 of high penetrating power 270KV (Code: Type C) |

| HUATEC-SUPER-2D Network Interface Box |

1pc |

|

| Connection cable |

1pc |

| Highly reliable notebook computer |

1pc |

|

| 300M AP WiFi Module |

1pc |

|

| Software (Installed) |

1pc |

|

| 3D Imaging Control Box Unit |

1pc |

DR equipment applications: HUATEC SUPER -3D DR (Digital Radiography) detection is widely used in industrial testing, medical, security inspection and other fields, industrial testing users covering aviation, aerospace, petrochemical, archaeological, manufacturing, veterinary industry and so on. The company's industrial DR meets all digital ray testing standards, including welds, castings, corrosion testing standards, including metal, non-metallic, composite material testing, and even cable archaeological purposes, can be portable or can be installed in the Automatic or semi-automatic tooling, can be applied to the testing room can also be applied to the workshop site and field testing, is the only highly integrated on the market engineering and systems equipment.

X-ray digital direct imaging system consists of imaging plate, X-ray machine, wireless control module, AC cable, X-ray machine synchronization control unit, data line, network interface box, portable computer and software components. Application of the coverage of the pipeline and with a coating with the media in the pipeline corrosion testing, can automatically measure the wall thickness thinning and corrosion pits; pressure vessel and pipe welding quality testing (butt welding, spiral welding, etc.) plate butt weld (Welding, laser welding, friction welding, diffusion welding, resistance welding, etc.); in-service liquid ammonia pipe corrosion and weld detection, casting loose porosity and inclusions detection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!