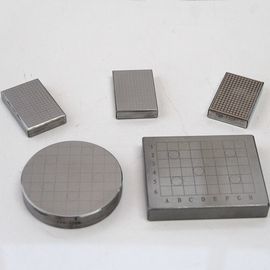

Rockwell block / Brinell block Portable Hardness Tester support HRA, HRC, HRB Hardness Test Blocks

Brinell hardness block:Range of 8 ~ 650 HBW

Brinell hardness measurement principle is to use a certain test force F (N), the size of the diameter D (mm) of the quenching steel or hard alloy ball pressure into the surface of the metal being measured (figure 1), after the prescribed time unloading test force, with a reading microscope to measure indentation average diameter D (mm), and then, according to the formula and brinell hardness HB value or D from has been prepared based on brinell hardness scale found in HB values.

As the metal materials are hard and soft, the measured workpiece is thick and thin, large and small, if only a standard test force F and pressure head diameter D, will appear to some workpiece and material inappropriate phenomenon. Therefore, in the production of brinell hardness test, can use different size of test force and the pressure head diameter, for the same kind of materials with different F when testing and D, it can get the same brinell hardness value, the key lies in the geometry of the indentation of the similar, can establish and D F a matching relationship, to ensure the invariance of brinell hardness.

Features: generally speaking, the smaller the brinell hardness, the softer the material, the larger the indentation diameter; Conversely, the larger the brinell hardness, the harder the material, the smaller the indentation diameter. The advantage of brinell hardness measurement is that it has high measurement accuracy, large indentation area, can reflect the average hardness of the material in a large range, the hardness measured is also more accurate, the data repeatability is strong.

Application: brinell hardness measurement method is applicable to cast iron, non-ferrous alloy, all kinds of annealed and tempered steel, it is not suitable to measure too hard, too small, too thin and the surface is not allowed to have larger indentation pattern or workpiece.

According to the national standard (GB231-84), the ratio of 0.102f /D commonly used in brinell hardness test is 30, 10 and 2.5. According to the types of metal materials, hardness range and thickness of samples, the diameter D, test force F and retention time of test head (steel head) are selected according to the following table (brinell hardness test specification).

Rockwell hardness test is a simple and rapid hardness test method. Rockwell hardness test method is widely used in manufacturing and scientific research. Rockwell hardness test is to apply the test force (initial test force and total test force) on the surface of the tested material with the standard pressure head twice, and then press the pressure head into the surface of the sample under the action of the test force. In total test force after a certain period of time, remove the main test force, to keep the initial test force under the condition of measuring depth, pressure to the total test force down into the depth and in the early test force under the difference between the pressure into the depth of the residual pressure (the so-called depth) to characterize the level of hardness, residual pressure into the depth, the greater the hardness value is lower, and vice versa. The sign for rockwell hardness is HR. In order to adapt to the application of different materials, rockwell hardness scale (A, B, C, D, E, F, G, H, K, L, M, P, R, S, V...

Vickers hardness measurement principle is basically the same as brinell hardness, is also based on the indentation unit area of the load to calculate the hardness value. The difference is that the pressure head of vickers hardness test is the regular quadric pyramid of diamond. During the test, under the action of a certain load, a square cone indentation is pressed on the surface of the sample. The diagonal length of the indentation is measured and divided by the surface area of the indentation. The value of the load divided by the surface area is the hardness value of the sample, represented by the symbol HV.

Vickers hardness code: HV

Unit: kN/was

Vickers hardness - a criterion for hardness of a material. It was first proposed by British scientist vickers. With the load of 49.03~ 980.7n, press the material surface of the square tapered diamond press with the opposite Angle of 136°, keep the specified time, measure the diagonal length of the indentation, and then calculate the hardness according to the formula. It is suitable for the hardness measurement of larger workpiece and deeper surface layer. Vickers hardness still has a small load vickers hardness, test load 1.961~< 49.03n, it is suitable for thinner workpiece, tool surface or coating hardness measurement; Microvickers hardness, test load <1.961N, suitable for the hardness determination of metal foil, very thin surface layer.

HV- is suitable for microscopic analysis. Vickers hardness (HV) is determined by pressing a diamond square cone press with a load of less than 120kg and a top Angle of 136° into the material surface and dividing the load value by the surface area of the indentation pits.

The vickers hardness tester has a wide range of measurements, from very soft materials (several vickers hardness units) to very hard materials (3,000 vickers hardness units).

Shore hardness block:

TYPE D shore block:1 box of 7 pieces, each in a different color

Test range HA32 HA46 HA52 HA55 HA72 HA81 HA87

Purple coffee green orange red yellow black

Shore hardness - introduction to shore hardness

TYPE A shore block: 1 box of 3 pieces, each in a different color

Test range HD14 HD29 HD88

Orange black gray transparent

Generally, feel elasticity is relatively large or soft products, testers can directly determine the use of shore A hardness tester test, such as: stationery bottles, TPU TPR plastic film bags and other products. And feel is basically not elastic or hard can be tested with shore D hardness tester, such as: PC ABS PP and other products. If the degree is shaw Axx, the hardness is relatively low, if the degree is shaw Dxx, the hardness is relatively high.

Supplement:

Shaw's units are not enough:

1. The unit expression for type A is :HA

2. Type D unit expression is :HD

| Products |

Specification |

Measure(u. mm) |

| Rockwell block |

(28-88)HRA |

Φ60×10 |

| (20-65)HRC |

| (88-100)HRB |

| Rockwell Superficial block |

(79-91)HR15N |

Φ60×10 |

| (42-80)HR30N |

| (20-70)HR45N |

| (88-93)HR15T |

| (70-82)HR30T |

| (55-72)HE45T |

| Brinell block |

(150-600)HBW 10/3000 |

Φ90×15 |

| (150-600)HBW 5/750 |

| (150-600)HBW 2.5/187.5 |

Φ64×12 |

| (75-125)HBW 10/1000 |

Φ90×15 |

| (75-125)HBW 5/250 |

| (75-125)HBW 2.5/62.5 |

Φ64×12 |

| Hammer Brinell block |

(150-500)HBW 5/750 |

12×12×150 |

| (150-500)HBW 5/3000 |

14×14×150 |

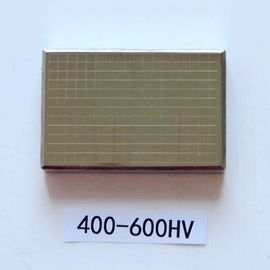

| Vickers block |

(150-750)HV5 |

Φ60×10 |

| (150-750)HV10 |

| (150-750)HV30 |

| Micro vickers block |

(200-300)HV0.05 |

Φ25×5 |

| (200-300)HV0.1 |

| (400-500)HV0.1 |

| (400-500)HV0.2 |

| (700-800)HV0.2 |

| (700-800)HV0.5 |

| (700-800)HV1 |

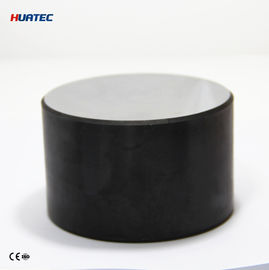

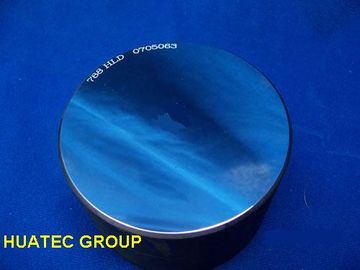

| Leeb hardness block |

(490-570)HLD |

Φ90×55 |

| (590-670)HLD |

| (750-830)HLD |

| Leeb hardness block for device G |

(460-540)HLG |

Φ120×70 |

| (550-630)HLG |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!