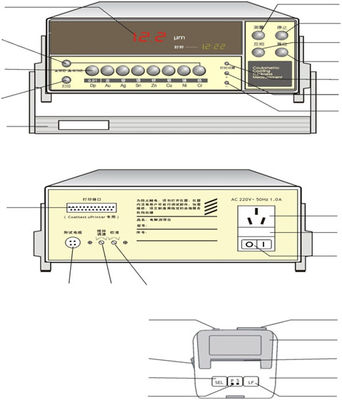

TG-100E Coulometric Thickness Tester Metal Coating Thickness Gauge Electrolytic Thickness Gauge

TG-100E coulometric thickness gauge, using anode dissolution coulomb method, conforms to ISO2177 standard. It can measure chromium, nickel, copper, zinc, tin, silver, gold, cadmium and other metal coatings, nickel alloy coatings, composite coatings (such as Cr/Ni/Cu) and multilayer nickel coatings.

FEATURES

- Permits measurement of thickness of single layer of electroplating metals

- The preset standard plating types are: decorative chromium, hard chromium, nickel, copper (copper on iron or non-metallic substrate), zinc, tin, silver, and gold 8 plating types. If you want to test other plating types, you must modify the preset plating types. For example, if you need to test electroless nickel (customers may not test silver), you can change silver to electroless nickel.

- Permits measurement of thickness of individual layers of multi-layer electroplated coatings

- Permits measurement of thickness of electroplated coatings on non-conducting materials such as plastics

- Digital display permits easy and accurate direct readings of measured thickness in the decimal system

- Equipped with a miniature printer, which can automatically print plating species, thickness and test time

- Potential difference cannot be measured

- Designed for use in accordance with the standard testing procedures conforming to the ISO Specification

SPECIFICATIONS

Model: TG-100E

Power supply: AC 220V±10%, 50~60Hz

Power consumption: Not more than 25 W

Gross weight: About 9 kg

Size of package: 370×440×230(mm) for the tester body

Measurement range: 0~50μm error: ≤±10%

Detailed list:

TG-100E tester body 1

Potential testing stand 1

The signal cable for potential transducer 1

Electrolysis cell 1

Gasket 1

Electrolysis solutions A2, A4, A5, A8 1

Rubber 1

Portioning bottle 2

Nipper 1

Instruction, guarantee card 1

Inspection prior measurement

- Place the tester, testing stand and the stand of the chemicals on the working desk in even and straight.

- Be sure that the power supply is AC 220V.

- Connect the tester to testing table using cables.

- Depress any select plating button, short out the signal clip to the terminal of signal plug, turn on the power switch and then depress the measurement button, the stirrer should rotate and the displayed begin to count. Disconnect the connecting line between the signal clip and the terminal of signal plug, the tester should immediately stop to count and alarm. Thus the condition of the tester can been considered as normal.

How to select the electrolytic solutions

Designation of electrolytic solutions and deposited metal and base combinations

|

Plating

metals

|

Base |

| Steel |

Copper and its alloys |

Aluminum |

Nickel |

Multi-layer

nickel

|

NdFeB |

| Gold(Au) |

|

A1 |

|

A1 |

|

|

| Silver(Ag) |

A6 |

A7 |

|

A6 |

|

|

| Tin(Sn) |

A3 |

A3 |

|

A3 |

|

|

| Zinc(Zn) |

A8 |

A8 |

A8 |

A8 |

A8 |

A8 |

|

Copper

(Cu)

|

A4 |

A4 |

|

A4 |

|

A4 |

| Nickel(Ni) |

A5 |

A5 |

|

|

|

A10 |

|

Chromium

(Cr)

|

A2 |

A3 |

A2 |

A2 |

A2 |

|

How to measure the plating metals of single layer

Example: The measurement of the zinc plating with white passivation on the steel substrate , it’s thickness is 10μm.

- Use the rubber to wipe away the passivation films on the surface of zinc plating of the article to be measured.

- Depress the testing head vertically on the surface of the article to be measured, applied adequate pressure until without any leakage.

- Electrolytic solution A8 is selected from table 2 for the combination of zinc plating on steel substrate. The cell must be filled with 2 ml of the electrolytic solution by using a dropper. The cell will not be filled full. (The solution level is about 3 mm from the opening of the cell)

- Insert pipette to the bottom of the electrolysis cell, repeat suck several times in order to remove the air bubble from cell, enables the electrolytic solution to contact completely with the zinc plating, before placing the stirrer to given position.

- Depress the Zn button.

- Insert the signal plug into the hole of the screw of the electrode, attach the red signal clip to the plated object and be sure that a proper connection has been done.

- press the measurement button, the stirrer begin rotating, while the buzzer alarms, the measurement will be stopped automatically, the thickness 10 μm has been displayed on the indicator, press the stop button.

- Press the print button to get the list of the measurement results. (if you don’t need the list you can skip this step)

- Raise the stirrer, clean up the used electrolytic solution by using the pipette, rise the testing head, remove the article.

- Clean up the internal surface of the cell and gasket by rinse water and wiping. Be sure that there is not any oxidation products on them before they are replaced back.

Note

When measure the plating of Au or Cr (decorate chromium), depress the T button and the Au or Cr button at the one time.

|

How to measure the hard chromium plating

Example: The measurement of the hard chromium plating on steel substrate , the thickness of the hard chromium plating is 35μm.

- Use the rubber wipe away the passivation films on the surface of chromium plating of the article to be measured.

- Depress the testing head vertically on the surface of the article to be measured, applied an adequate pressure until without any leakage.

- Electrolytic solution A2 is selected from table2, the cell must be filled with 2 ml of the electrolytic solution by using a dropper. The cell will not be filled full. (The solution level is about 3 mm from the opening of the cell)

- Insert the pipette into the bottom of the electrolysis cell. Repeat suck several times, in order to remove the air bubble from the cell, enables the electrolytic solution to contact completely with the chromium plating.

Note: When measuring the chromium plating placing the stirrer is not a requirement.

- Depress the plating of Cr select button and the Cr measurement button. (the plating of Cr select button: --- measure the decorate chromium --- measure the hard chromium)

- Insert the signal plug into the hole of the screw of the electrode, attach the red signal clip to the plated object and be sure that a proper connection has been done.

- press the measurement button, the stirrer begin rotating, when the thickness of 15μm shows on the indicator press the stop button then press the print button(if not the tester could not work normally), renew the electrolytic solution, again press the measurement button. Renewal of the electrolytic solution should be made at frequency of even 15μm until buzzing. Record the thickness of the hard chromium plating.

- Clean up the used electrolytic solution by using the pipette. Rise the testing head. Remove the article.

- Clean up the internal surface of the cell and gasket by rinse water and wiping. Be sure that there is not any oxidation pro ducts on them before they are replaced back.

How to measure the multi-layer plating

Example: The measurement of the thickness of the multi-layer deposits consisting of copper,nickel and chromium plating on the steel substrate . The thickness of the component layers is 0.4μm of chromium, 14μm of nickel, 10μm of copper.

- Use the rubber wipe away the passivation films on the surface of plating on the article to be measured

- Depress the testing head vertically on the surface of the article to be measured, applied an adequate pressure until without any leakage.

- Electrolytic solution A2 is selected from table2, the cell must be filled with 2 ml of the electrolytic solution by using a dropper. The cell will not be filled full. (The solution level is about 3 mm from the opening of the cell)

- Insert the pipette into the bottom of the electrolysis cell. Repeat suck several times, in order to remove the air bubble from the cell, enables the electrolytic solution to contact completely with the chromium plating.

Note: When measuring the chromium plating placing the stirrer is not a requirement.

- Depress the T & Cr measurement button.

- Insert the signal plug into the hole of the screw of the electrode, attach the red signal clip to the plated object and be sure that a proper connection has been done.

- Press the measurement button, the stirrer begin rotating, while the buzzer alarms, the measurement will be stopped automatically, the thickness of 0.4μm has been displayed on the indicator, repeat press the measurement button 1~2 times, and buzzing before pressing the stop button. Record the thickness of the chromium plating (the measurement values is based on the values obtained from first buzzing).

- Clean up the used electrolytic solution by using the pipette without rising the mount of the cell. Rinsing the cell 1~2 times with deionization water before filling the cell with 2ml of the electrolytic solution A5 (refer to Table 2, the electrolytic solution A5 for nickel plating on copper substrate), and then placing the stirrer to giver position.

- Repeat the step 7 as above and record the thickness 14μm of the nickel plating.

- Repeat the steps 7, 8 as above and record the thickness of 10μm of the copper plating.

- Clean up the used electrolytic solution by using the pipette. Rise the testing head. Remove the article.

- Clean up the internal surface of the cell and gasket by rinse water and wiping. Be sure that there is not any oxidation products on them before they are replaced back.

The formulations and preparation methods of the electrolytic solutions

Requirement: The electrolytic solution requires preparation from the analytical pure grade of the chemicals and the distilled water.

| Symbol |

Name |

Molecular formula |

Preparation methods |

| A2 |

Phosphoric acid |

H3PO4 |

Use water to dilute 127ml H3PO4 to1000ml. |

| A3 |

Hydrochloric acid |

HCl |

Use water to dilute 175ml HCl to 1000ml. |

| A4 |

Ammonium

nitrate

|

NH4NO3 |

Use water to dissolve and dilute 800g

NH4NO3, 10ml NH3·H2O to 1000ml.

|

|

Ammonia

aqueous

|

NH3·H2O |

| A5 |

Ammonium

nitrate

|

NH4NO3 |

Use water to dissolve and dilute 400g

NH4NO3 40g NaSCN to 1000ml.

|

|

Sodium

thiocyanate

|

NaSCN |

| A6 |

Sodium nitrate |

NaNO3 |

Use water to dissolve and dilute 5ml HNO3, 100g NaNO3 to 1000ml. |

| Nitric acid |

HNO3 |

| A7 |

Potassium

thiocyanate

|

KSCN |

Use water to dissolve and dilute 180g KSCN to 1000ml. |

| A8 |

Sodium chloride |

NaCl |

Use water to dissolve and dilute 100g NaCl to 1000ml. |

| A1,A10 |

|

At present, those formulations not been published, for purchase. Please contact with us |

All models guide:

TG-100D and TG-100E

① TG-100D and TG-100E are traditional economical instruments. TG-100G uses computer resources to form a virtual instrument through corresponding software, which is more powerful.

② TG-100E is an improved type of TG-100D, equipped with a miniature printer, which can automatically print plating species, thickness and test time.

③ The surface of the NdFeB product is microporous. During the electrodeposition process, nickel deposits penetrate into the pores of the matrix to form a layer of inconspicuous interface, so there is no potential mutation characteristic of conventional interfaces. Conventional thickness measuring instruments Unable to determine the measurement end point correctly. Using the TG-100G electrolytic thickness gauge, the simultaneous measurement of thickness and potential can effectively solve the problem of measuring the coating of neodymium iron boron permanent magnets.

④ Multi-layer nickel coating measurement uses TG-100G electrolytic thickness gauge, which can analyze the thickness and potential difference of each layer of nickel through the curve.

The difference between TG-100D and TG-100E is: TG-100D has no printing function, no clock display, other properties are the same.

TG100-E economic model

Thickness gauge selection TG100-E is the most popular model that can meet most test requirements.

1. The preset standard plating types are: decorative chromium, hard chromium, nickel, copper (copper on iron or non-metallic substrate), zinc, tin, silver, and gold 8 plating types. If you want to test other plating types, you must modify the preset plating types. For example, if you need to test electroless nickel (customers may not test silver), you can change silver to electroless nickel.

2. Standard configuration Probe: diameter 2.4mm (also 1.7mm, 1.2mm, 1.0mm, 0.8mm optional) The machine is equipped with only one type probe, so customer need to tell the smallest workpiece size, try to choose a large probe which the accuracy will be better

3 . Potential difference cannot be measured

4. Simple information can be printed: plating type, thickness, test time

TG-100G all-round type

1. It can complete all the functions of TG-100E type

2. It can measure the potential difference of multi-layer nickel

3. It can use two kinds of probes, usually 2.4mm and 1.7mm.

4. The data can be stored in the computer and read at any time.

5. Printable A4 testing report

TG-208 new model

1. It can complete all the functions of TG-100E

2. It can change to a variety of probes, usually 2.4mm and 1.7mm

3. It can easily complete wire measurement without conversion factor

4. Print complete test data: every Sub-data, maximum value, minimum value, average value, standard deviation, tester, test time, test times. Multi-plated test data can be displayed in one report at the same time.

5. Potential difference cannot be measured.

Scope of application

- If there is no special requirement, TG -100D and TG-100E can be competent such as mobile phone and camera buttons, car knobs, hardware tools, electronic and electrical components, showers, faucets, shelves, sports equipment, bicycles, standard parts, kitchen supplies, bathroom supplies, locks, doors Handle, car signs, door cabinet accessories, motorcycles, automobiles, connectors, wires, welding wires, neodymium iron boron

2. TG-100G is more focused on the automobile, motorcycle, and sanitary ware industries, because these industries will use the potential difference function. And neodymium iron boron industry, to solve the test problems of the underlying nickel. Automobiles such as: signs, car door locks, car handles, car interior parts, motorcycles such as mufflers, motorcycle brackets, sanitary wares such as: mixing water valves, towel racks, neodymium Iron-boron: mainly nickel-copper-nickel electroplating

3. TG-208 is similar to TG-100E type in application, easy operation, complete functions, rich printing content, and easy operation for wire testing is its biggest highlight. No domestic product can compare with it.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!